Modular Truck Wheel Cleaning Solution

Portable & Scalable, Cost-Effective, Maintenance-Free

No Water or Electricity Needed

No Civil Works or Council Approvals

Australian Made with Certified Compliance

EPA Compliant Design

Quote & schedule in two business days or $500 credit

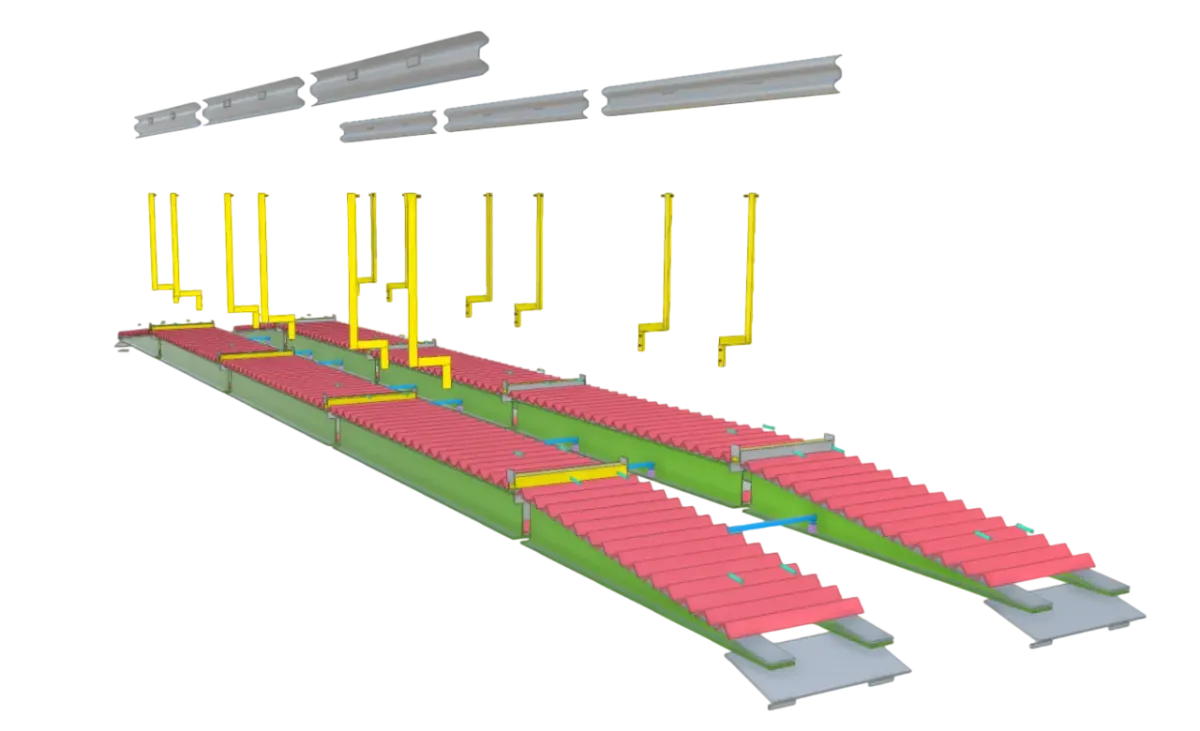

Modular Wheel Cleaning System

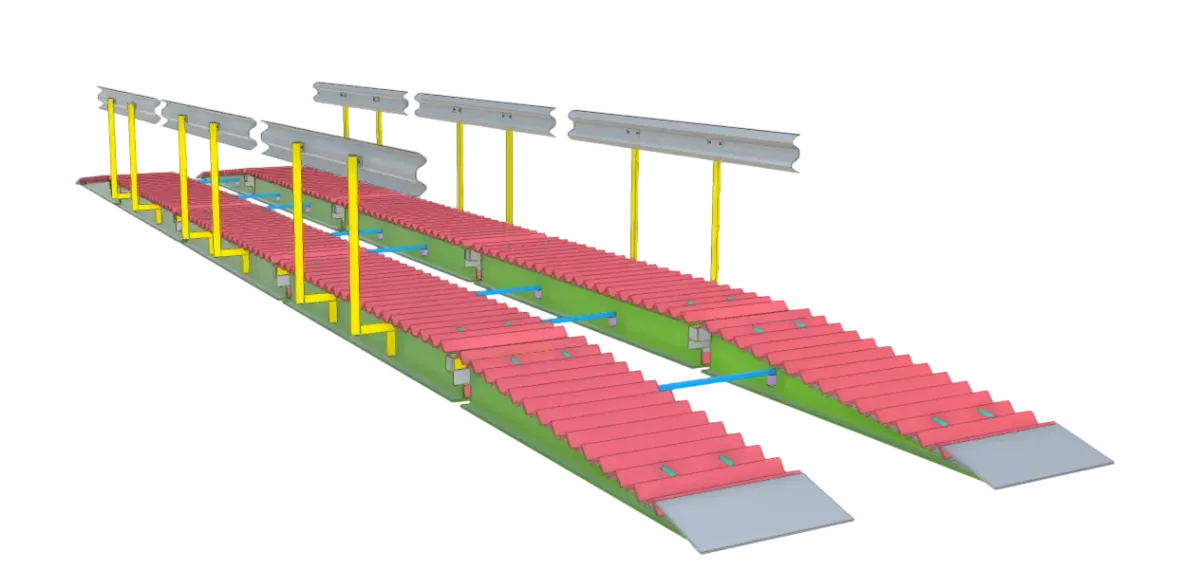

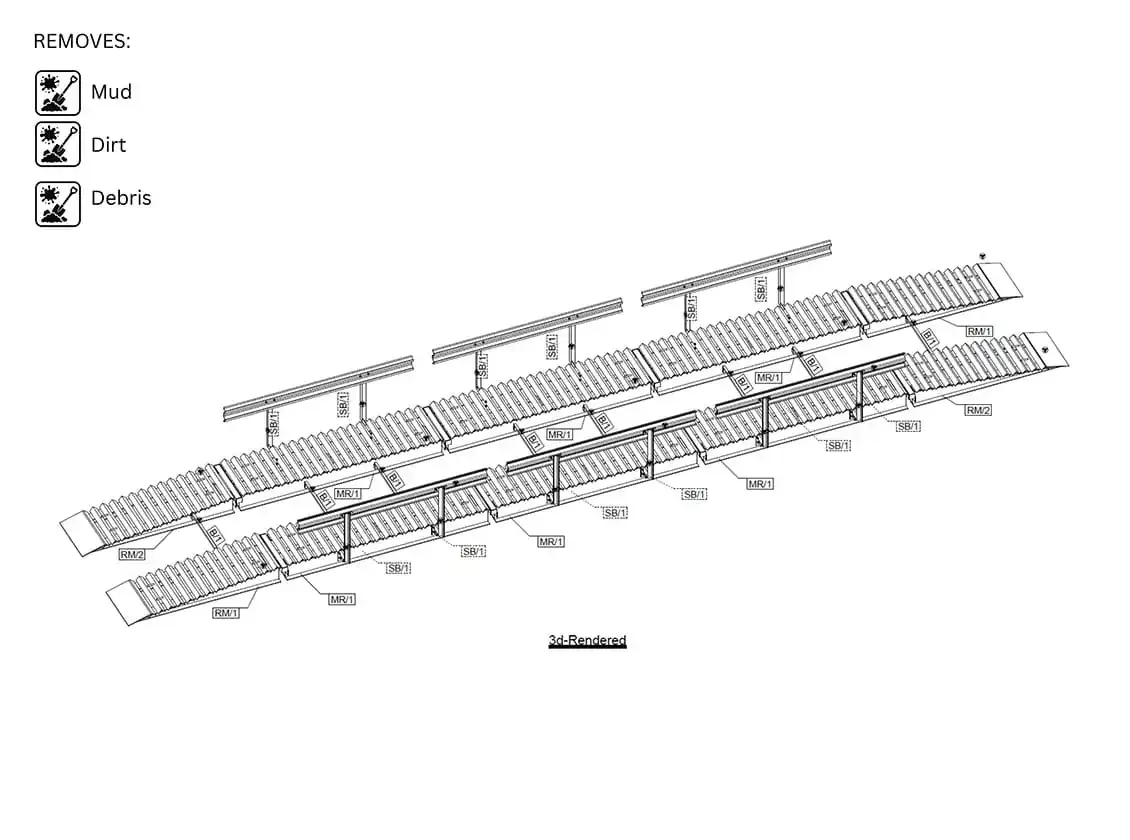

The CoreHQ Modular Wheel Cleaning system (MWC-12T) is a fully above-ground, dry wheel wash solution engineered for remote and environmentally sensitive sites. Requiring no water, electricity, civil works, or council approvals, it offers a 12-tonne per axle load capacity and can be set up in under an hour, making it ideal for industries like mining, construction, and agriculture.

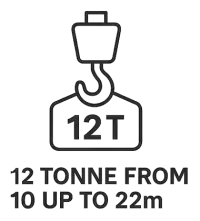

Load rating: Rated to handle up to 12 tonnes per axle, making it suitable for the heaviest commercial and industrial vehicles.

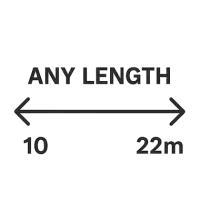

Footprint: 10m to 18m to 22m long and 3.06m wide. Modular design allows flexible configuration to suit different site layouts.

Turn-key kit: Supplied with heavy-duty steel pad, rumble-grid entry/exit ramps.

Ideal applications: Perfect for mining, construction, quarries, agriculture, and any site requiring robust wheel cleaning without water or power.

Product Summary

100% Above Ground

The system is entirely above-ground, eliminating the need for excavation or permanent foundations. This design allows for rapid deployment and easy relocation without disturbing the site.

No Water Required

Operates without water, making it ideal for remote or drought-affected areas. This dry cleaning approach reduces environmental impact and conserves resources.

No Electricity Needed

Functions without electricity, allowing deployment in off-grid locations. Its gravity-assisted mechanism ensures effective cleaning without power dependency.

No Civil Works

Requires no civil works, enabling rapid setup without construction delays. The modular design simplifies installation and minimizes site disruption.

No Council Approvals

Does not necessitate council approvals, streamlining the deployment process. This feature accelerates project timelines and reduces administrative burdens.

No Trade Waste Permit

Eliminates the need for trade waste permits, simplifying compliance requirements. By avoiding water usage, it sidesteps regulations related to wastewater disposal.

Features & Benefits

Heavy Duty Design

Built to handle high-frequency use in rugged environments, the system supports heavy machinery and trucks. Its reinforced steel construction ensures long-term durability and low maintenance needs.

12 Tonne Per Axle Load Rating

Engineered to withstand up to 12 tonnes per axle, it accommodates large commercial vehicles with ease. This makes it suitable for industries like mining, construction, and agriculture.

Modular & Scalable

The system’s modular design allows it to be extended or reconfigured as needed. It can scale with project demands or site changes, ensuring long-term flexibility.

3 Wheel Rotations Cleaning

With a length of up to 22 metres, vehicles make three full wheel rotations over the cleaning surface. This maximizes the removal of mud, dirt, and debris without needing high-pressure water jets.

Ramp Technology

How the mud and debris are removed

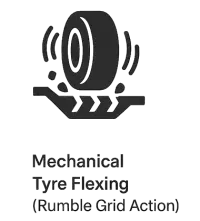

Mechanical Tyre Flexing – Rumble Grid Action

Uses the natural flexing and movement of tyres as they roll over specially designed rumble grids to dislodge mud and debris trapped in tyre grooves. This passive cleaning method effectively removes dirt without water or mechanical brushes, leveraging the tyre’s own motion for eco-friendly wheel cleaning.

Gravity Assisted Drop Through

The cleaning process relies on gravity to let dirt and debris drop through the gaps naturally, without extra force or water. The two downward arrows reinforce the concept of gravity pulling the debris down.

Debris Collected Below Ramp

As vehicles pass over the ramp, loosened mud and debris fall through the rumble grid and are captured in a containment tray or collection pit below. This keeps the ramp surface clear for continuous use and allows for easy maintenance and environmental compliance.

100% Mechanical

The system operates entirely through mechanical design, with no need for electricity, hydraulics, or water. This ensures reliable performance in remote or off-grid locations, with minimal maintenance and zero energy consumption.

Why CoreHQ?

Certified Compliance

Engineer-signed drawings for council or mine-site approval.

24-Hour Response

Quote & schedule in two business days or $500 credit.

On-Shore Fabrication

Predictable lead-times.

Performance Warranty

5-yr frame / 12-mo workmanship.

Client Reviews

“The dry wheel cleaning system has been a game-changer for our remote site operations. It’s easy to set up, requires no water, and keeps our vehicles compliant without the usual mess — highly recommend!”

— James L., Operations Director, CivilEdge Group

“We were skeptical at first, but this system truly delivers. No water, no brushes, just efficient cleaning that saves us time and avoids costly environmental permits.”

— Lena M., Sales Manager,

Innovex Equipment

“Perfect for our mining fleet — durable, low maintenance, and works in off-grid locations with no power required. Our wheels stay clean, and our site stays green.”

— Darren K., Project Lead,

MineTech Solutions

“Since installing the dry wheel wash, mud and debris buildup has significantly reduced, improving safety and vehicle performance. The quick setup and modular design make it ideal for our changing site needs.”

— Anita R., Marketing Head,

FluidSystems Inc.

Get a Free Quote or Ask a Question

Fill out the form below or call us on 1800 524 002 directly. Receive a quote and schedule in two business days or get $500 credit

Disclaimer: All information is kept secure and will not be shared or sold to any third party.

T&C: Free quote is available with no obligation. Please consult with our staff for full details.

About Us

We connect urgent buyer demand with certified Australian manufacturers—fast, safe, and guaranteed. One partner. One contract. Total accountability.

Quick Links

Copyright © 2025 | CoreHQ. All Rights Reserved.

Web Design by YEWS | Privacy Policy | Disclaimer